Electrolux shapes living for the better by reinventing taste, care and wellbeing experiences, making life more enjoyable and sustainable for millions of people.

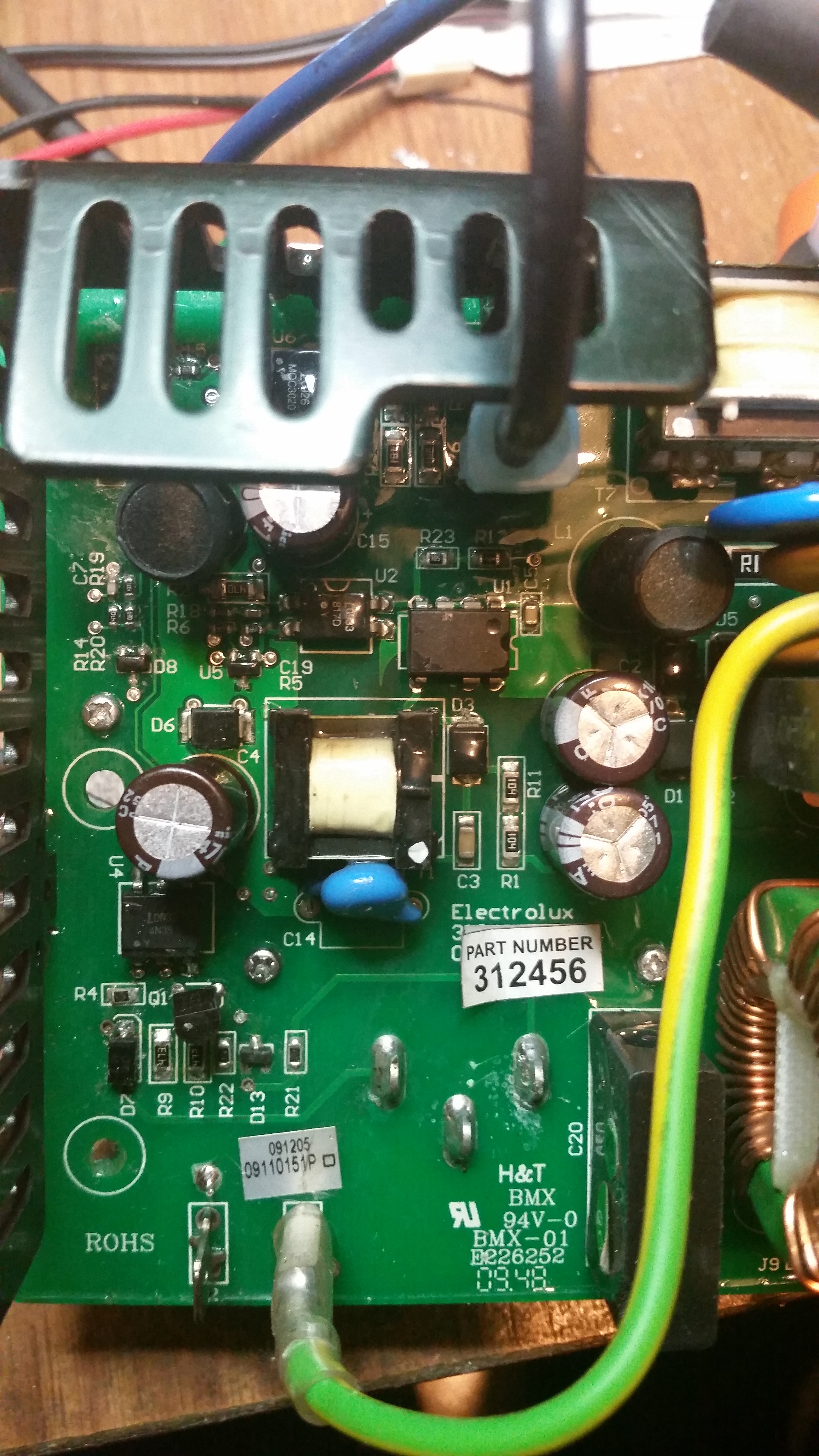

Find premium kitchen and laundry appliances for your home including refrigerators, dishwashers, ranges, cooktops, washers and dryers at ElectroluxAppliances.com. To make this repair you will need a Phillips screwdriver, a flat blade screwdriver, a quarter-inch nut driver, and a pair of channel lock pliers. For this installation, work gloves are recommended. Note that this piece may look different or be a different color than the original, but this part will fit and function in the same way as the. Can't wait to wash clothes with your brand new Electrolux washing machine? Follow this installation guide to get your washing machine up and running.1. Used impact driver with phillips attachment to remove two of the three screws that hold the bearing to the back of the drum (these are on the inside) The third screw's head stripped out and I had a very difficult time removing it. Had it not been for that, the job would have taken less than an hour. This video provides step-by-step repair instructions for replacing the drive belt on an Electrolux washing machine. The most common reasons for replacing the.

As a leading global appliance company, we place the consumer at the heart of everything we do. Through our brands, including Electrolux, AEG, Anova, Frigidaire, Westinghouse and Zanussi, we sell more than 60 million household and professional products in more than 150 markets every year.

Electrolux has been doing business since 1919. The headquarters are located in Stockholm, Sweden, and the Electrolux share ELUXb is listed on Nasdaq OMX Stockholm. For more information go to www.electroluxgroup.com

Electrolux Offering

Electrolux products include refrigerators, dishwashers, washing machines, cookers, vacuum cleaners, air conditioners and small domestic appliances. The Group is the only appliance manufacturer in the world to offer complete solutions for both consumers and professionals.

Electrolux Purpose

Our future is determined by the way we all live our lives. That’s why we strive to improve everyday life for millions of people and the world around us. It is embodied in everything we do. In every idea, every product and every human interaction.

We believe that outstanding taste experiences should be easy for everyone. That there is always a better way to care for our clothes to make them look and feel new longer. That the home should be a place for wellbeing, a place to care for ourselves and our loved ones.

To succeed, we continuously rethink and improve our ways of working – internally, and together with our customers and partners.

By creating desirable solutions and great experiences that enrich peoples’ daily lives and the health of our planet, we want to be a driving force in defining enjoyable and sustainable living.

This is us – at Electrolux we shape living for the better.

Mission

We reinvent taste, care and wellbeing experiences for more enjoyable and sustainable living around the world.

Electrolux Dryer Problem

To create these experiences we focus our innovation on three areas:

We help people make great tasting, healthy food for friends and family. An oven that cooks evenly or a hob with precise temperature controls and high speed, can enable consumers and give them the confidence and skills to do well.

We help consumers care for their clothes by making them stay new and great looking for longer. Electrolux delivers solutions that allow consumers to put their favourite clothes into the washing machine and be completely confident in the result.

People are concerned about the air that they breathe and their environment. We call that wellbeing. Electrolux helps consumers get a better home environment through floor care, air care and water care.

Drivers

The purpose is underpinned by three drivers: Act Sustainably, Create Better Experiences and Always Improve. The drivers guide our behaviours, give direction to our strategies, and convey the core of how we behave as a company.

Act sustainably

Inspire and contribute to a change for the better.

We are determined to shape living for the better of our customers and for the health of our planet. We are proud of our Scandinavian heritage and our accomplishments, but we intend to improve further and to make smarter, more resource efficient solutions available for everyone. To develop better operations for our co-workers and the communities around us. To always act ethically and respect human rights. To work together with customers and professional partners who share our desire to change for the better.

Create better experiences

Design solutions that elevate the everyday.

Experiences are in the food our customers put on their plate, the way they care for their clothes, the quality of the air they breathe or the water they drink. Better experiences not only elevate our customers’ every day, but are also mindful of our society and our planet.

Always improve

Think new and never settle.

We never settle, and are always curious and forward leaning. We see opportunities where others see problems and make things happen. That is what it takes to shape living for the better.

Any problem with your Electrolux dryer? Please select an error code in the tables below to reveal the fault and a how to fix it yourself. Remember to check the name of your model first, as we have separate error code lists for different models.It is very important to find the right list, as Electrolux produces a really wide variety of dryers with slightly different structure. In addition to dryers, the Swedish company makes a diverse range of household appliances. It is known as the second largest manufacturer in the world.

| Error Code | Label | Description | Solution |

|---|---|---|---|

| E10 | General EEPROM Fault | Problem with communication between EEPROM and the microprocessor. | Clear code, exit mode and start dryer. If problem persists, replace electronic control. |

| Ell | Checksum Error | Problem with communications or memory did not check, one has become corrupted. | Clear code, exit mode and start dryer. If problem persists, replace electronic control. |

| E12 | Non fetal R/W error | Problem reading or writing to the memory or input/output. | Clear code, exit mode and start dryer. If problem persists, replace electronic control. |

| E24 | Control NTC Short Circuit | Control thermistor or its wir- ing is shorted. | Remove wires from control thermistor. Measure resistance of thermistor. If reading is not 50 K (± 10%), replace thermistor. If reading is within 50 K (±10%), check wiring between thermistor and electronic control. If good, replace electronic control. |

| E25 | Control NTC Open Circuit | Control thermistor or its wiring is open. | Remove wires from control thermistor. Measure resistance of thermistor. If reading is not 50 K (± 10%), replace thermistor. If reading is within 50 K (±10%), check wiring between thermistor and electronic control. If good, replace electronic control. |

| E4A | Program Time out Fault | The drying time has exceeded program time for that cyde. | Press PAUSE CANCEL and SELECT buttons for 6 seconds to exit test modes. Position cyde selector to NORMAL, temperature selector to HIGH HEAT and touch START. Check for anything that would extend dry times such as: no heat, restricted vent, blower fan blade broken or loose, dryer installed in closet with solid door, or bad connection in moisture sensor bar arcuit or dirty bars. If dryer operates normally but code returns, replace electronic control. |

| E5B | Heater Fault (no heating) | Temperature reading of control thermistor has not changed in a certain amount of time. | Position cyde selector to NORMAL, temperature selector to HIGH HEAT and touch START. Measure voltage across terminals on relay RL2 (heater relay) on electronic control. If meter reads 240V on electric models and 120V on gas models, replace electronic control. If meter reads zero, remove power from dryer. Disconnect wire going to NO terminal on the relay RL2. Reconnect power and measure voltage drop between terminal COM on relay RL2 and neutral. If meter reads zero, wire between incoming line and relay RL2 is open. If meter reads 120V, check the rest of the heater circuit. |

| E68 | Key (button) Struck Fault | One of the keys (buttons) is stuck dosed (active). | Enter function test mode and perform key (button) test to determine which button is at fault. Carefully free the key (button) and perform the test again. If button is free but the key struck code still exists, replace electronic control. |

| E8C | Too many trips in a period of time. | The safety (high limit) thermostat has tripped too many times within a certain period of program time. | Check for blocked lint filter, blocked exhaust, air leaks around air duct, broken blower fan blades, worn or loose drum seals, dryer installed in closet with solid doors or door seal not correctly seated. |

| EAF | Watch Dog Reset | Microcontroller has been reset by internal Watchdog timer. | Clear code, exit mode and start dryer. If problem persists, replace electronic control. |

Electrolux affinity dryer error codes

| Error Code | Description |

|---|---|

| E31 | Moisture Sensor: Oscillation Frequency to High |

| E41 | Door Open at Cycle Start |

| E42 | Door Sensing Failure |

| E43 | Door Open During Cycle Execution |

| E51 | Motor Relay Failure |

| E52 | Motor Fault- Motor Stopped or Not Starting |

| E54 | Motor Sensing Failure |

| E61 | Heater Relay Failure |

| E63 | Heater to Earth Ground Failure |

| E64 | Heater Open Circuit |

| E65 | Heater Thermostat Trip Count too High |

| E66 | High Limit Thermostat Circuit Open |

| E67 | Heater Sensing Failure |

| E68 | Thermal Limiter Open Circuit |

| E71 | NTC 1 Open Circuit |

| E72 | NTC 1 Short Circuit |

| E91 | No Communication Between Main Board and User Interface |

| E92 | Protocol incongruence between main board and User Interface |

Electrolux EIED55HIW – 8.0 cu. Ft. Electric dryer error codes

| Error Code | Fault | Possible Fault Conditions | Possible Solutions |

|---|---|---|---|

| E31 | Contact Sensor frequency too high | Electronic Control Board defective or foreign object interfering with contact sensor | Check Contact Sensor and wiring. If no problems are found with Contact Sensor, replace Electronic Control Board. |

| E32 | Contact Sensor frequency too low | Electronic Control Board defective or foreign object interfering with contact sensor | Check Contact Sensor and wiring. If no problems are found with Contact Sensor, replace Electronic Control Board. |

| E42 | Door Sensing failure | Electronic Control Board defective | Replace Electronic Control Board. |

| E51 | Motor Relay failure | Motor Relay stuck open or closed; Wiring defective | If motor runs continuously with power applied check for short circuit across motor relay (RL2). or L1 applied to motor relay output (J3-1) with cycle stopped. If motor does not start when 'start' key is pressed, check for open circuit between L1 and motor relay connection (J3-2). If no wiring problems found, replace Electronic Control Board. |

| E52 | Motor Fault - motor stopped or not startinq | Motor overheating: Laundry load too heavy: Low power supply: Motor, or Wirina defective | Remove any load from dryer and check if drum turns freely by hand. Check L1 power supply voltage, motor wiring, and motor thermal protector (if motor thermal protector has tripped, it may take up to 30 minutes to reset). |

| E53 | Motor Centripetal Switch Failure | Motor Centripetal Switch. Electronic Control Board Defective, or wiring defective. | Check wiring. Check if Motor Centripetal Switches are stuck in open or closed positions. Replace motor. Replace Electronic Control Board. |

| E54 | Motor Sensing failure | Electronic Control Board defective | Replace Electronic Control Board and retest. |

| E61 | Heater Relay failure | Heater relay stuck open or closed; Wiring defective | Check for short circuit across heater relay(s) (RL5. RL6. RL7) or L1 applied to heater relay output(s) (J5-2, J7-1, J7-3) with cycle stopped. Check for open circuit between L1 and heater relay connection(s) (J5-1, J5-3, J7-2). If no wiring problems are found, replace Electronic Control Board and retest. |

| E63 | Heater to Earth Ground | Heating element or wiring defective | Check heater coils and connections for short circuits to the cabinet. Replace heater and/or wiring and retest. |

| E64 | Heater Open Circuit | Heating element or wiring defective | Check heater coils and connections for open circuits. Replace heater and/or wiring and retest. |

| E65 | High Limit Thermostat trip count too high | High vent restriction. High Limit Thermostat defective or Inlet Thermal Limiter tripped (Electric Model only) | For Electric Model, check Inlet Thermal Limiter for continuity. If Thermal Limiter is open, check for evidence of high temperature event and any resulting damage. If no further damage is evident, replace Thermal Limiter. If no problems are found with the Thermal Limiter, check exhaust vent system for air blockages. If no problems with vent restrictions, check/replace High Limit Thermostat, and retest. |

| E66 | Thermal Limiter Open Circuit | Outlet Thermal Limiter tripped Inlet Thermal Limiter tripped (Gas Model only) or wiring defective | Check Outlet Thermal Limiter for continuity. For Gas Model, also check Inlet Thermal Limiter for continuity. If Thermal Limiter is open, check for evidence of high temperature event and any resulting damage. If no further damaqe is evident, replace Thermal Limiter and retest. |

| E67 | Heaters Sensing Failure | Electronic Control Board defective | Replace Electronic Control Board and retest. |

| E71 | Outlet Control Thermistor open circuit | Outlet Control Thermistor or wiring defective | Check resistance of Outlet Control Thermistor, and check wiring for open circuit. Resistance should be between 4.9K Ohm and 6.2K Ohm at room temperature (68-77° F or 20-25° C). Replace Outlet Control Thermistor and/or wiring and retest. |

| E72 | Outlet Control Thermistor short circuit | Outlet Control Thermistor or wiring defective | Check resistance of Outlet Control Thermistor, and check wiring for short circuit across Thermistor connections. Resistance should be between 4.9K Ohm and 6.2K Ohm at room temperature (68-77° F or 20-25° C). Replace Outlet Control Thermistor and/or wiring and retest. |

| E73 | Inlet Control Thermistor open circuit | Inlet Control Thermistor or wiring defective | Check resistance of Inlet Control Thermistor, and check wiring for open circuit. Resistance should be between 47K Ohm and 66K Ohm at room temperature (68-77° F or 20-25° C). Replace Inlet Control Thermistor and/or wiring and retest. |

| E74 | Inlet Control Thermistor short circuit | Inlet Control Thermistor or wiring defective | Check resistance of Inlet Control Thermistor, and check wiring for short circuit across Thermistor connections. Resistance should be between 47K Ohm and 66K Ohm at room temperature (68-77° F or 20-25° C). Replace Inlet Control Thermistor and/or wiring and retest. |

| E91 | Communication Error | Wiring. Electronic Control Board | Check connections between Electronic Control Board and Interface Board. If no wiring problems, replace Electronic Control Board or Interface Board. |

| E92 | Incompatible protocol | Electronic Control Board incompatible with Interface Board | Check if correct Interface Board console and Electronic Control Board are installed. Replace appropriate hardware. |

| E93 | Machine configuration checksum error | Wrong configuration data loaded. Interface Board or Electronic Control Board or wiring defective | Check if correct Interface Board and console are installed. Replace Interface Board and/or console. |

| E94 | Cycle configuration checksum error | Wrong configuration data loaded or Electronic Control Board defective | Replace Electronic Control Board. |

| E97 | Program mismatch | Wrong configuration data loaded. Electronic Control Board defective | Replace Electronic Control Board. |

| EA1 | Main Supply Frequency out of Range | Line frequency out of limits or Electronic Control Board faulty | Check frequency of line voltage. |

| EA2 | Voltage too high | Line voltage too high or Electronic Control Board faulty | Check amplitude of line voltage. |

| EA3 | Voltage too low | Line voltage too low or Electronic Control Board faulty | Check amplitude of line voltage. |

| EA4 | Improper home wiring | Line connections in home faulty, wiring or Electronic Control Board defective | Check wiring at terminal block for L1-N-L2 wired incorrectly. |

| EA5 | Main V Sensing failure | Electronic Control Board defective | Replace Electronic Control Board. |

| EF1 | Vent Blocked | High vent restriction. Exhaust Control Thermistor. Inlet Control Thermistor, or Electronic Control Board defective | Check vent restrictions and resistance values of Exhaust Control Thermistor and Inlet Control Thermistor. |

| EF3 | Max Timeout Timer | Exhaust blocked; Exhaust Control Thermistor. Inlet Control Thermistor. Contact Sensor or Electronic Control Board defective | Check vent restriction. Contact Sensor, and resistance values of Exhaust Control Thermistor and Inlet Control Thermistor |

| EF8 | Key Stuck | Console button or Interface Board defective | Check buttons for activation when pressed. Replace console or Interface Board as appropriate |

Electrolux T4130 dryer error codes

| Error code | Description |

|---|---|

| E 01 | Option Not in use. |

| E 02 | Option Not in use. |

| E 03 | Inlet air - Sensor has short-circuited The thermistor element measuring the air inlet temperature to the drum, or the wiring to the sensor has shorted. |

| E 04 | Outlet air - Sensor has short-circuited The thermistor element measuring the air outlet temperature from the drum, or the wiring to the sensor has shorted. |

| E 05 | Fan motor Motor 1: The thermal protection switch in the motor, or its harness, is open. |

| E 06 | Drum motor - Motor 2: The thermal protection switch in the motor, or its harness, is open. |

| E 07 | Option Not in use. |

| E 08 | Inlet and Outlet air protection thermostats One of the proctection thermostats has opened due to overheating. |

| E 09 | Option Not in use. |

| E 10 | Setting Programming error / incorrect or missing parameter(s). |

| E 11 | Drying error Maximum allowable RMC time exceeded (non-coin operated models only). |

| E 12 | Drying error Maximum allowable Autostop time exceeded (non-coin operated models only). |

| E 13 | Drying error - Requested drying time is longer than maximum allowed.(dryer connected to a payment system). |

| E 14 | Gas error - A flame was not detected on gas heated dryers. |

| E 15 | Vacuum switch The vacuum switch/pressostat does not shut within 12 seconds after the dryer is started. |

| E 16 | Vacuum switch The vacuum switch/pressostat was already closed when an attempt to start the dryer was made. |

| E 17 | Inlet sensor disconnected The inlet thermistor or wiring to the thermistor is open. |

| E 18 | Outlet sensor disconnected The outlet thermistor or wiring to the thermistor is open. |

| E 19 | Option Not in use. |

| E 20 | CMIS out of operation The dryer is put out of order in the PC programme. |

| E 21 | CMIS com board poll error The PC does not poll the dryer within the time out. |

| E 22 | LM10 com board poll error The PC does not poll the dryer within the time out. |

| E 23 | Option Not in use. |

| E 24 | Condensate container The condensate container is full and the pump is not pumping. |

Electrolux T4300S dryer error codes

| Code | Cause/Solution |

|---|---|

| Error code E05 or E06 | When the error code E05 or E06 is displayed,this can be due to the motor being too hot. Stop the dryer and wait for 5 minutes. Start again and choose a program. If this does not help and the error code reappears a service technician must be contacted. |

| Error code E12 | When the error code is displayed this can be due to the user having overfilled the dryer with clothes that are too wet. Remove some of the clothes, close the door, and press the start button. If this does not help and the error code reappears a service technician must be contacted. |

| Error code E14 | When resetting gas error the dryer must be in operation on a program with heat, and the heat indicator must be on. The dryer must only be reset three times. If the dryer, however, has to be reset more than three times it has to be put out of order and a service technician must be called. |

| Error code E15 | When the error code is displayed this can be due to the user having overfilled the dryer. Remove some of the clothes, close the door, and press the start button. If this does not help and the error code reappears a service technician must be contacted. |

| Error code E16 | The error code is displayed if the user presses the start button while the air pressure switch is already activated. Resetting by opening / closing the door and pressing start button. |

Electrolux Diversity

Electrolux T5190 dryer error codes

Electrolux Driver Reviews

| Error code | Text | Cause/Action |

|---|---|---|

| 12.12 | DRYING ERROR WITH RMC PROGRAM | The longest permitted RMC time has been exceeded. (Applies only to machines with RMC). The machine is overfilled or the garment is too wet. |

| 12.11 | DRYING ERROR WITH AUTOSTOP PROGRAM | The longest permitted automatic stop time has been exceeded. (Applies only to machines with automatic stop). The machine is overfilled or the garment is too wet. |

| 12.10 | O.H. DRUM MOTOR | The motor is too hot. The machine will restart automatically when the temperature on the motor is OK (if the door has not been opened). |